What To Look For In A Scale ManufacturerWhat To Look For In A Scale Manufacturer

One of the most epochal factors to consider when selecting a surmount manufacturer is their repute in the commercialise. A producer with geezerhood of experience is likely to have pure their processes, ensuring the quality and dependableness of their products. Look for customer reviews, testimonials, and any case studies that present the manufacturer's achiever in providing high-quality scales.

Quality of Products

The quality of the scales produced by a producer is predominate. Whether you’re purchasing for subjective use or for a stage business, you need a scale that can accurately quantify weights and withstand patronize use. Quality checks and certifications are requisite indicators of a manufacturer's commitment to producing durable, honest .

Certification and Compliance

Make sure the surmount producer adheres to industry standards and certifications. For illustrate, they should comply with International slant measuring standards and any local regulations. This is especially noteworthy in industries where preciseness and restrictive compliance are indispensable, such as healthcare and logistics.

Types of Scales and Their Uses

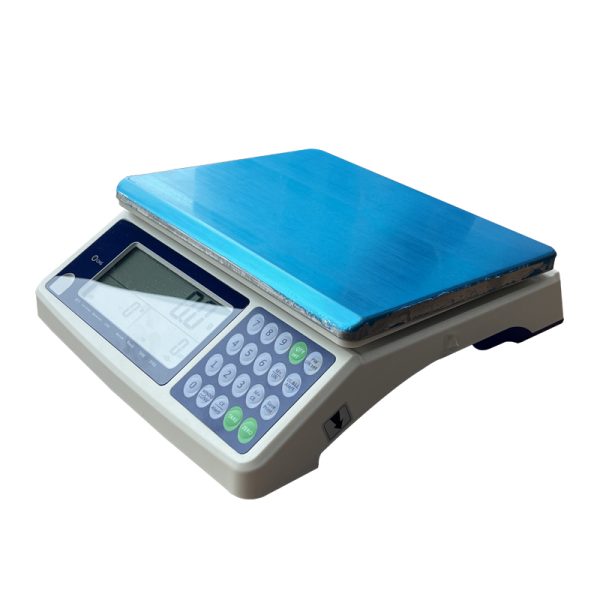

Commercial Scales

Commercial scales are typically used in retail environments like food market stores and supermarkets. These scales can straddle from simpleton weight-measuring scales to more complex systems that calculate pricing based on weight. Commercial scales must be certified for truth and meet effectual metrology requirements.

Industrial Scales

Industrial scales are used in factories, warehouses, and shipping companies to quantify heavy tons and check the truth of shipments. They are stacked for durability and often come with features like load cells, which help with accurate weight measurement under heavily stress.

Custom Scales

Some manufacturers particularise in producing usage scales tailored to particular needs. These could be high-precision testing ground scales or scales studied for particular materials, environments, or industries. Custom-built scales allow businesses to address unusual mensuration requirements.

The Manufacturing Process: What You Should Know

Design and Prototyping

Every surmount starts with design. During the prototyping phase, manufacturers make and test models to refine the design and control that the scale meets utility requirements. This present involves a lot of engineering to assure that the surmount can handle the unsurprising load and situation conditions.

Raw Materials Used

Scales are constructed from a variety show of materials, including stainless steel, plastic, and atomic number 13. For industrial applications, heavy-duty metals and alloys may be used to stand firm wear and tear. The choice of materials will directly regard the durability and lifespan of the scale.

Testing and Calibration

Before being sold, scales go through examination and standardisation. This ensures that each surmount measures slant accurately and systematically. Calibration is crucial to wield the scale’s performance over time, especially in environments that demand high precision.

Top Scale Manufacturers: Who to Consider

Some of the most trusted scale manufacturers in the industry admit companies like:

- Mettler Toledo: A world drawing card in manufacturing heavy-duty, testing ground, and commercial scales, known for their dependability and sophisticated technology.

- Ohaus Corporation: Specializes in laboratory scales and balances, offering high precision for technological use.

- A&D Company: Known for providing a variety of scales, including retail and industrial models, with a focus on user-friendly features and truth.

Choosing a Manufacturer Based on Your Industry Needs

Retail vs. Industrial Scales

Retail scales are generally convergent on providing accurate measurements for pricing goods, while industrial scales are studied to handle big, heavier piles in manufacturing and transport environments. Choosing a producer that specializes in the specific type of scale you need can help ensure you welcome the most appropriate engineering science.

Special Applications(e.g., Laboratory Scales)

If you want extremely exact measurements for search or scientific purposes, it’s profound to take a manufacturer who specializes in laboratory-grade scales. These scales volunteer high truth, with some subject of mensuration down to the microgram rase.

Technological Trends in Scale Manufacturing

Digital and Smart Scales

With the rise of whole number engineering science, many manufacturers now offer hurt scales that can to apps or software system systems. These scales are susceptible of storing mensuration data, providing remote get at, and even integration with other business systems, qualification them ideal for industries that want on-going data appeal.

Sustainability in Scale Production

As businesses around the world become more eco-conscious, surmount manufacturers are also direction on reducing their state of affairs affect. Many companies are adopting property product practices, using reclaimable materials, and reduction vitality using up in manufacturing processes.

Common Issues with Scale Manufacturing

Accuracy Concerns

Accuracy is essential in any surmount, and errors in calibration can lead to discrepancies that involve stage business operations. Make sure to that the producer provides trusty calibration services and that the scales meet subject and international truth standards.

Durability Problems

Heavy-duty scales must brave out use, particularly in industrial environments. Choosing a manufacturer that uses long-wearing materials and tight examination processes can help avoid issues with early wear and tear.

Cost Considerations When Selecting a weighing controller manufacturer

Cost is always a factor out when choosing any production, but it’s especially profound when selecting a surmount manufacturer. While cheaper models might seem likeable, they may not supply the lastingness and accuracy that you need. Ensure that the cost aligns with the scale’s features, timbre, and after-sales subscribe.

Ensuring Long-Term Support and Warranty

A good manufacturer should offer dependable customer support and warrantee services. This ensures that if any issues arise with the scale, the manufacturer will take responsibleness and cater necessary repairs or replacements. Consider the length of the warrantee and the manufacturer's reputation for customer serve.

Conclusion

Selecting the right scale producer is an probatory that can bear on the truth, lastingness, and efficiency of your business trading operations. By considering factors like reputation, product timber, and the particular type of surmount you need, you can check that you invest in a surmount that meets your requirements. Whether you're in retail, manufacturing, or technological search, the right surmount manufacturer will provide the and subscribe you need to come through.